Best MES Software

-

PRODUCTS

-

BUYER'S GUIDE

Buyer's Guide

By Christina George, Technical Content Writer at SelectHub

Optimizing production without data insights is like building a Lego set without the instruction booklet. MES software gives you the tools to “Moneyball” your manufacturing processes by tracking production progress and making data-backed decisions.

In this buyer’s guide, we’ll dive deeply into all things MES. We’ll chalk out benefits, features, deployment, implementation goals, trends and top products to give you an edge in the software selection game.

Executive Summary

- MES solutions collect valuable information on production lines to make data-driven decisions, manage equipment and workforce on the shop floor to maximize production and track production progress in real time.

- Its core functions include data collection and acquisition, scheduling, process management, staff and resource management, machine monitoring, performance analysis and document management.

- Check with vendors about domain expertise, deployment, integrations and scalability before purchasing a solution.

- What Is MES Software?

- Deployment Methods

- Primary Benefits

- Implementation Goals

- Basic Features & Functionality

- Advanced Features To Consider

- Current & Upcoming Trends

- Software Comparison

- Cost & Pricing Considerations

- The Best MES Software

- Questions To Ask Yourself

- Questions To Ask Vendors

- Next Steps

- Product Comparisons

What Is MES Software?

MES software is a production-oriented platform designed to optimize production by managing, monitoring and synchronizing processes. It leverages digital work instructions, product routing and connections to production machinery to build traceable product records. Users can access critical information about production activities on the factory floor across various departments in the organization.

It monitors and controls manufacturing operations and information flow across the shop floor. Real-time operation allows users to control multiple elements of the production process, including inputs, personnel, machines and more. Supervisors and managers can gauge current operating conditions on the shop floor and optimize them to boost production output.

Deployment Methods

Cloud deployment is the new cool kid on the block. Industry leaders predict the cloud is the future of MES. However, it’s currently far from the norm. Ultimately, the type of deployment you choose depends on your company size, infrastructure, type of product and budget. Here’s a brief overview of the three types available: cloud-based, on-premise and hybrid.

Cloud-Based

Using a vendor-hosted cloud platform is a great way to minimize support and tech costs, access shop floor data remotely, and reduce your initial investment. It is a great option for smaller and mid-size companies with a straightforward product and a tighter budget. However, you may find the customization a touch basic, and you will need to rely on vendor support for fixes and updates.

On-Premise

More locations mean more reasons to get an on-premise solution to meet your needs. This deployment method is for you if you already have a tech team, the infrastructure to house your system and the budget. On-site deployment allows you to custom-build the platform with features, integrations and add-ons, manage security and grow as you go. On the downside, it requires a massive investment, and any bugs or malfunctions will need in-house attention.

Hybrid

You get the best of both worlds with a hybrid MES system. Manage operations on-premise and handle analytics on the cloud. It allows users to view data remotely, avoid security risks and reduce system maintenance costs.

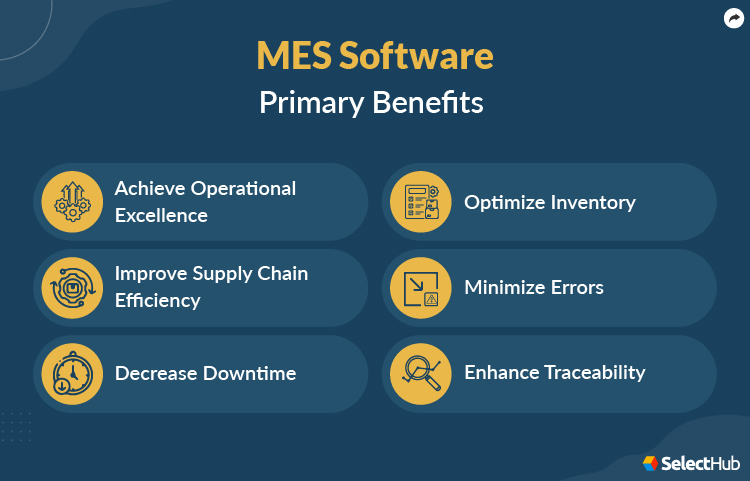

Primary Benefits

Convincing anyone to shell out thousands of dollars for new software is a tough job. But we’ll take a crack at it. Here are the benefits MES can bring to your business.

- 3D Printing

- Additive Manufacturing

- Apparel ERP

- Business Management

- Carpet Cleaning

- Cleaning Service

- Discrete Manufacturing

- Distribution

- EDI

- ERP

- Field Service

- Food Distribution

- Food Manufacturing

- Food Safety

- Food Traceability

- GPS Tracking

- HVAC

- Job Management

- Job Scheduling

- Lawn Care

- Locksmith

- Manufacturing BI

- Manufacturing Inventory

- Manufacturing

- MRO

- MRP Systems

- MSP

- PDM

- Pest Control

- Pharmaceutical Manufacturing

- PLM

- Plumbing

- Pool Service

- Production Tracking

- PSA

- Routing

- Service Scheduling

- Simulation

- Time And Expense Tracking

- Work Management

Achieve Operational Excellence

You’ve got 99 problems, but making data-backed decisions won’t be one. Access real-time production data and track current processes and associated bottlenecks to optimize throughput and improve asset efficiency.

Improve Supply Chain Efficiency

Identify deviations in performance targets to gauge root causes of operational inefficiencies. Use data insights to take corrective actions to improve supply chain efficiency.

Decrease Downtime

According to Forbes, 82% of companies experienced unplanned downtime incidents in the last three years. Track raw materials and parts inventory to create realistic production schedules that balance resources. Minimize time spent reconfiguring schedules and eliminate machine downtime while parts are in transit.

Optimize Inventory

Storing surplus inventory is never a good idea, as the shelf-life of raw materials tends to deteriorate over time. Update records with real-time inventory information to keep stakeholders aware of availability. Eliminate costly and time-consuming warehousing and monitoring of unnecessary inventory.

Minimize Errors

Paper records, manual entry and slow response times can lead to mistakes. Use paperless records to eliminate human errors and provide a centralized database for information.

Enhance Traceability

Accidents happen. In manufacturing, you need to know when, why and how. Using manufacturing data, monitor the entire production process and group batches or final products. Demonstrate regulatory compliance with full process traceability and production records.

Expert recommendations and analysis on the top MES software

Implementation Goals

| Goal 1 Improve Quality Control | Monitor machine and process data, use digital work instructions and conduct real-time quality control checks to improve process and product quality and document product exceptions. |

|---|---|

| Goal 2 Implement Paperless Manufacturing | Use digital work instructions, electronic order dispatches and electronic records to eliminate paper waste, human errors and multiple databases. |

| Goal 3 Optimize Manufacturing Processes | Sync and track shop floor activities across departments and plants and connect them to optimize performance. Pinpoint and resolve issues using real-time feedback to improve processes. |

Expert recommendations and analysis on the top MES software

Basic Features & Functionality

| Process Execution Management | Define process plans with details like execution sequence rules, work instructions, resources and data collection requirements. Guide technicians through process execution using instructions, including setting up tools and position parts, running machines and performing verifications. Track order completion using resources, bill of materials, operation area and other criteria to gain granular visibility into the production process. Use insights to plan inventory, schedule production and inform customers about tentative delivery dates. |

|---|---|

| Data Collection | MES is the name, and making data-driven decisions is the game. Capture production data related to personnel, machines, material consumption and quality enabling stakeholders to access real-time info through dashboards and reports. Monitor and track machine status through interfaces, industrial protocols or sensors to measure KPIs such as overall equipment effectiveness and machine uptime to identify bottlenecks and points of failure in production processes. |

| Labor Management | Track production personnel clock-in and clock-out data and absence times to schedule labor efficiently. Implement an incentives-based system using production data, absence time and work order time to calculate performance levels. Enable role-based access to ensure authorized personnel can use specific machinery, tools and work orders on the shop floor. |

| Quality Management | Quality is king in manufacturing. Capture and process data throughout the production life cycles using the Control Batch Record. Track and record deviations from setpoint values to determine if it is within tolerance limits and trigger an alert to inform stakeholders. |

| Resource Management | Manage production resources like tools, machines and materials to ensure optimum resource utilization. Control operating resources, determine available tools, and evaluate their condition for preventive maintenance to reduce downtime. |

| Product and Part Tracking | Leverage barcode scanners to track products moving from one work center to another. Track material expiration dates to prevent personnel from using expired materials and maintain product quality. Monitor parts as they move through shop floor storage areas until they are installed or used in production operations. |

| Mobile Capabilities | Accessibility is changing the way manufacturing systems operate. Capture electronic signatures, verify users, log in using fingerprint sensors, and upload pictures and files into records. |

| Reports and Dashboards | Make reporting easy again with this module. Create customizable dashboards with moveable widgets to show on-time and late manufacturing orders in progress, sales, stocks, cash flow and purchases. Configure grouping fields, define and select fields to customize templates and export reports in PDF or Excel formats. |

Expert recommendations and analysis on the top MES software

Advanced Features & Functionality

| SPC (Statistical Control Analysis) | Want to reduce waste and increase efficiency? Crunch the numbers with SPC. Measure and analyze data, collect test samples and check for rule exceptions to improve processes. |

|---|---|

| Change Management | All things change, including products and processes. Manage product revisions, update work instructions and process plans and reference changes in the product definition via eBOMs and CAD models. |

| Downtime Management | Monitor, track and report machine energy usage and downtime to create records, determine causes of downtime and schedule better in the future. |

| OEE (Overall Equipment Effectiveness) Analysis | There’s nothing like real-time data to help determine actual performance. Analyze OEE using performance data, production count, waste and historical data. Generate reports using custom KPIs to visualize production line performance. |

| Customer Complaint Management | Customer feedback can be an unexpected source for actionable improvement. Convert claims into inspections to pinpoint why a quality issue arose. |

Expert recommendations and analysis on the top MES software

Current & Upcoming Trends

It is a truth universally acknowledged that the wheel of technology keeps spinning and we must embrace changes or risk being left behind. What was current yesterday may be obsolete tomorrow (or even today). Here are some MES trends to keep in mind when shortlisting products.

Advanced Reporting and Predictive Analytics

Look for a vendor that provides data management options for advanced reporting and predictive analytics capabilities. Use machine learning algorithms to gain robust insights from massive data sets to identify bottlenecks and take corrective actions to improve production processes.

AI and Automation

Increasing demand for customization and smaller batches mean automated tracking, planning and scheduling of manufacturing operations is a necessity. Currently, some platforms help users respond to issues on the shop floor with AI-powered predictive modeling and recommendations.

Track and Trace

Compliance is everything in most industries. The food and beverage, plastics and pharmaceutical industries need travel and trace capabilities. Look up the genealogy of your product, track products from raw materials to finished goods and automate data collection and reports.

Software Comparison

Manufacturing execution systems aren’t one-size-fits-all. Just like you need specific machinery to create your product, you need the right software to make your production processes sing. Assess the following factors when selecting an MES solution:

Domain Expertise

Does your MES solution address the unique and complex needs of your specific manufacturing areas? Does your vendor have experience in your industry? The nation (and your supervisors) need to know. Cross-check with customers using the solution to discover its ins and outs and look at industry specializations.

Scalability

It’s safe to assume your business will scale over time. You’ll need to account for new suppliers, distribution partners and service providers and a system that can grow as you do. Selecting a vendor who can deliver smart and connected IIoT-enabled devices with customizable interfaces is imperative to boost your scalability across the supply chain, ERP and CRM systems.

Integrations

Your MES system needs information from other solutions to put its best foot forward. Check if the solution offers APIs to build custom integrations with other software. Look for ERP, HRMS, BI and CMMS software integrations to boost performance.

Cost & Pricing Considerations

We’re not going to mince words here. MES software is a ginormous investment. Looking for a solution that offers a low-cost initial investment to deliver an adaptable solution that can upgrade easily and requires minimal maintenance support is ideal but may be unrealistic.

Initial implementation costs may include purchasing a subscription or license, hardware and implementation services from the vendor. On-premise deployment is usually more costly than on the cloud, so it may not be feasible for smaller businesses.

Additionally, you may need to shell out for internal staff training, software maintenance, service fees and support staff costs. Upgrades, add-on features and customizations will also add to the price tag.

Expert recommendations and analysis on the top MES software

The Best MES Software

Let’s consider the leading manufacturing execution systems you can leverage to fulfill business goals and objectives.

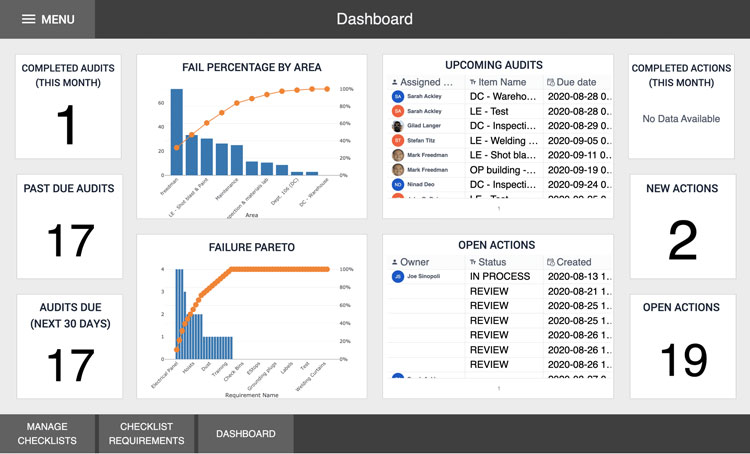

Tulip

Tulip is an on-site and cloud solution that monitors machines to identify bottlenecks, decrease downtime and boost production efficiency. It organizes and stores real-time production data in a customizable database. Users can create custom reports to view real-time defect rates, machine metrics and progress against production targets.

Tulip’s Customizable Dashboard.

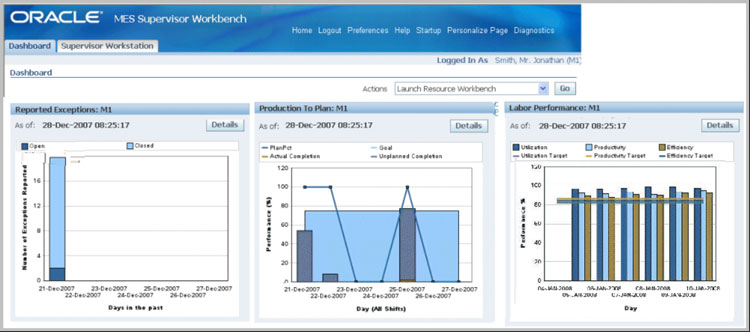

Oracle MES

Oracle MES is a hybrid solution designed to streamline production cycles. Users can increase productivity by tracking, recording and prioritizing production activities. It offers digital records, additional information, work instructions and signatures. Other capabilities include customizable reports and dashboards, a supervisor workstation and multiple integrations.

Demo Supervisor Workstation.

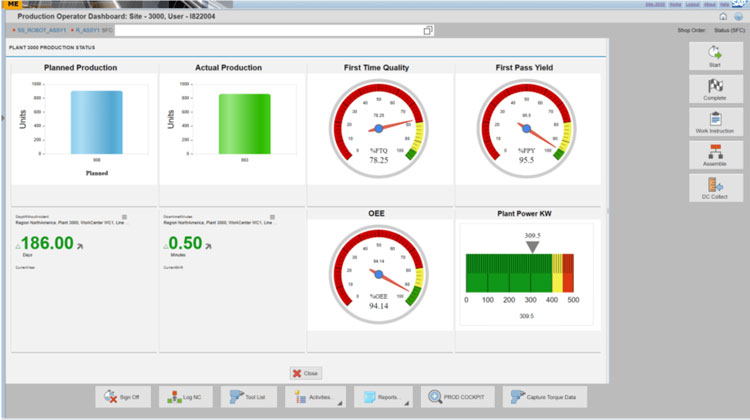

SAP MES

SAP MES is a cloud-based platform to optimize manufacturing processes with data tracking and automation. It offers centralized operations with user-based touch screens, automatic data collection and track and trace visibility across the supply chain.

Production Operator Dashboard.

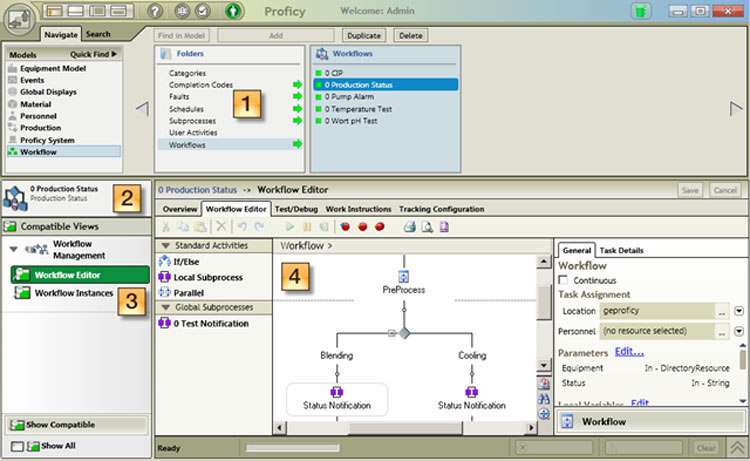

Proficy MES

Proficy MES is a web-based system suited to discrete, process and mixed manufacturing organizations. It helps users optimize production by converting shopfloor data into actionable insights. Additionally, robust production tracking, dynamic scheduling, hybrid data management and advanced AI analytics streamline performance.

Proficy Workflow Interface. Source

Lighthouse Systems

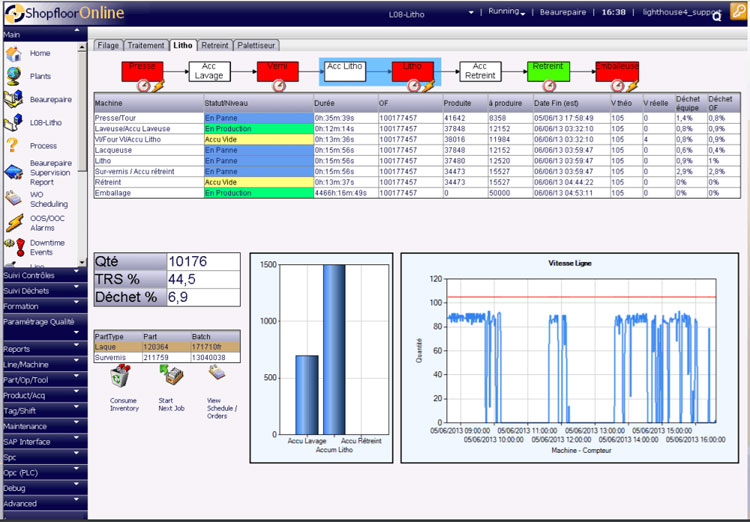

Lighthouse Systems is a cloud-based solution that uses a digital thread to streamline operations. It offers 26 modules providing real-time visibility into production, change management, quality assurance and inventory management. Other features include remote accessibility, CMMS, data analysis and multiple integrations.

Lighthouse Systems Dashboard.

Expert recommendations and analysis on the top MES software

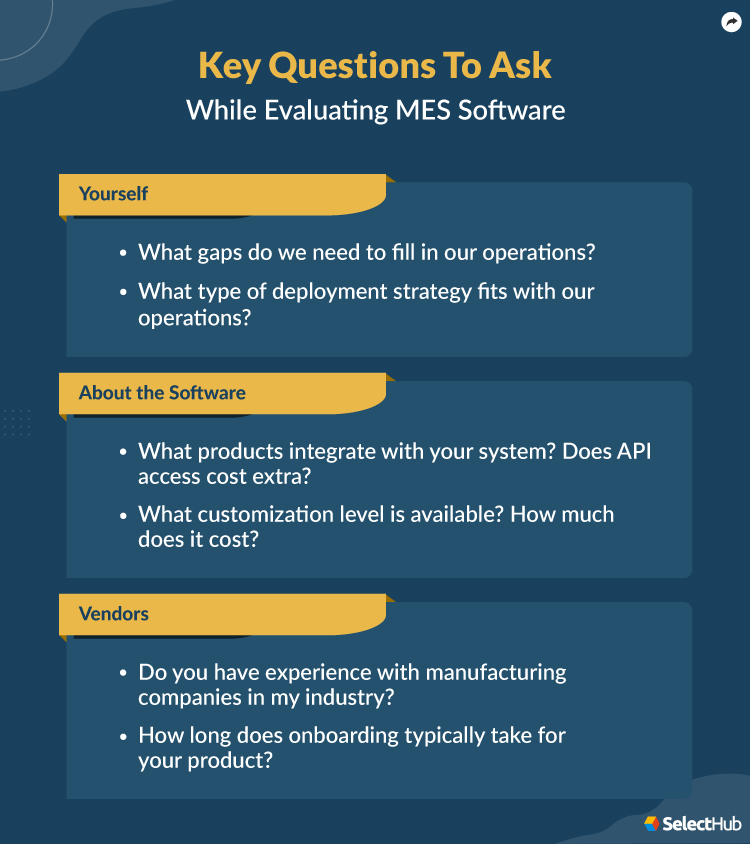

Questions To Ask Yourself

Before you get into any conversation with vendors, it’s critical to understand your requirements down to a T. Ask the following questions to clarify your company’s specific needs:

- What features are vital? What can we do without?

- Do we need a scalable solution to support growth?

- What gaps do we need to fill in our operations?

- What type of analytics and reports do we need?

- How difficult will the learning process be for our employees?

- Do we need additional hardware or software?

- Is compliance something we need to consider?

- What type of deployment strategy fits with our operations?

- What kind of internal infrastructure should the new system support?

Questions To Ask Vendors

Once you’re clear about what you need, you want to be sure the vendor can provide it. Ask the questions below to ensure you’re on the same page:

About the Software

- How often are updates offered? Do they happen automatically?

- How does the software handle automation levels, processes and volume changes?

- What products integrate with your system? Does API access cost extra?

- What customization level is available? How much does it cost?

- How much time does it take to deploy?

- How user-friendly is the interface?

About the Vendor

- What constitutes a successful deployment?

- How long does onboarding typically take for your product?

- What support services do you offer? Do they come with an additional cost?

- What training, knowledge resources or documentation can you provide to help train new hires?

- Do you have experience with manufacturing companies in my industry?

- Do you help with data migration, or will I need to hire a third-party vendor?

- What is the pricing model? How often does it change?

Expert recommendations and analysis on the top MES software

Next Steps

Buying new software is like signing a quarterback. It’s expensive, and you need to be able to make it work with your system (or resign yourself to shelling out a lot more cash). The right MES software should cater to your dynamic business needs and empower you with data-driven insights to help optimize production.

Tip the odds on lucking out with a new platform by using our free comparison report to see how products stack up against each other and your needs. Happy shopping!

Product Comparisons

Top 10 MES Software Leaders by Analyst Rating (of 86 products)

(of 86 products) GET THE IN-DEPTH REPORTProducts found for MES Software

Applied Materials

Applied Materials produces chips for advanced displays and modifies materials at atomic levels. Its forecast parts management module enables users to maintain the exact inventory needed to maximize production equipment’s use. It provides a customized spare parts kit with cleaning and coating services to reduce the total cost. Its automation capabilities improve process quality and boost factory and manufacturing equipment performance.

Aspen Technology

AspenTech is developed for companies in process industries, including energy, chemicals, engineering and construction. Its asset performance management module avoids unplanned downtime with accurate warnings of equipment failures and prescriptive guidance to mitigate issues. It automates workflows and orchestrates processes for seamless execution and improves performance. It leverages advanced optimization to develop optimal production plans and executable schedules.

Critical Manufacturing

Critical Manufacturing is a cloud-based, modular system enabling discrete manufacturing companies to improve performance and digitize with analytics and configurable tools. A single, integrated window for production data helps users make better-informed decisions.Its standout features include closed-loop quality management, digital twin and factory automation capabilities. Integrate with an IIoT-enabled workplace to create seamless smart factories. Users can create and implement a baseline at multiple sites to standardize production.

DELMIAworks

DELMIAworks (formerly IQMS) contains integrated processes such as supply chain, finances, CRM, capacity planning and employee activity boosts. It detects and addresses operation obstacles. Implement real-time intel to accommodate varying clientele needs and gain up-to-date operation snapshots. It's available for the cloud and on-premise deployments for better flexibility across industries and business sizes. Reduce scrap levels and boost repair times. It can also push for more on-time deliveries.

FactoryTalk

FactoryTalk helps manufacturers boost yield and productivity, enhance asset utilization and optimize resource management. Its automation and control capabilities enable food producers to respond to dynamic consumer demands and preferences while reducing production costs and improving product quality. It sets performance goals and tracks progress in real time. Household and personal care manufacturers can shorten product life cycles and improve time to market. It increases throughput and reliability while minimizing material costs. It caters to various industries, including chemical, food and beverages, automotive, infrastructure, metals, marine and more.

WinSPC

WinSPC is a reputable software system that ranks 6 among all MES Software according to our research analysts and 30 crowd-sourced reviews from 2 sources. Starting from $1600, WinSPC is priced on the high side, offers a free trial on occasion and is most advisable for all company sizes. WinSPC can be deployed in the cloud and on-premise and is accessible from a fewer number of platforms including Windows and Linux devices.

iBASEt

iBASEt is a solution for streamlining communication and improving manufacturing quality. Powered by Solumina, it improves real-time visibility and control over operational processes by offering a paperless production and quality system. It acts as a ‘digital thread’ and can be utilized on-premises, in the cloud or via a hybrid implementation.

VisualFactory

VisualFactory is an error-proofing solution that helps its users record manufacturing processes. It is designed for businesses operating within highly regulated industries. It reduces human error, eliminates paperwork and speeds up training time to maximize workforce potential. It provides access to real-time data and takes control of shop floors through track and trace serialization. Its tool and equipment maintenance module identifies service needs and replenishes parts to ensure smooth production.

SmartFactory

SmartFactory helps companies capture, analyze and visualize KPIs in real time using wireless sensors and advanced technologies. The identification and tracking module allows production staff to track inventory, materials and assets in real time. Its advanced vision inclusions provide reliable reading and verification of 1D/2D codes, text and object recognition. Downtime video analysis visualizes downtime events to save on product waste, decrease turnover times and increase revenue. Users can utilize IIoT devices to track machine production rates, monitor equipment vibration levels and prevent breakdowns.

ParityFactory

ParityFactory is a promising software tool that ranks 10 among all MES Software according to our research analysts and 6 crowd-sourced reviews from 2 sources. Starting from $1500, ParityFactory is priced on the high end and is most suitable for any company. ParityFactory can be deployed in the cloud and on-premise and is accessible from a fewer number of platforms including Windows and Linux devices.

Mar Kov

Mar Kov is a well-known application that ranks 118 among all Manufacturing Software according to our research analysts and 1 crowd-sourced review from 1 source. Starting from $2500, Mar Kov is priced on the high side, offers a free trial on occasion and is most applicable for companies large and small. Mar Kov can be deployed online and on-premise and is accessible from a fewer number of platforms including Windows and Linux devices.

TrakSYS

TrakSYS is a popular solution that ranks 12 among all MES Software according to our research analysts and 76 crowd-sourced reviews from 2 sources. Starting from $6500, TrakSYS is priced at a premium, offers a free trial on occasion and is most suitable for any business. TrakSYS can be deployed online and on-premise and is accessible from a limited set of platforms including Windows and Linux devices.

FactoryFour

FactoryFour is a cloud-based system designed to configure and analyze operations and scale production. It identifies bottlenecks across processes and balances resources throughout work centers for optimum resource utilization. It maintains a master schedule visible to project managers, operators and salespeople to simplify communication. Real-time alerting helps users respond quickly to production issues and alerts key stakeholders through customized emails or SMSs. It ensures operators’ productivity with responsive, Kanban-style dashboards.

Leading2Lean

Leading2Lean works with existing systems to digitize manual workflows, make data actionable and provide closed-loop methodologies for continuous improvement. Its workflow management module configures processes to fit the shop floor. The intelligent document association ensures correct documentation attachment to workflows. Its comprehensive dashboards help users understand current business status and multi-site reports. It offers multi-site analytics to identify enterprise weaknesses and uncover hidden patterns, correlations and insights.

ABB Ability

ABB Ability is a comprehensive solution that caters to automotive, mining, transportation, food and beverages industries. It helps mining companies improve productivity, reduce costs and safeguard fixed assets. It facilitates automation, data integration and real-time optimization of mining operations. It enables automotive manufacturers worldwide to strengthen employee productivity, product quality and worker safety. Connected services notify users about production line issues.

Megaventory

Megaventory is a cloud-based solution that helps manage stock and is designed for operations of all sizes, with a focus on streamlining operational processes. Robust reporting and manufacturing features provide valuable access to operational data that can be leveraged toward planning and forecasting. It offers several integrations that let users continue using workflows that fit their unique requirements. It supports value-added services such as kitting while also strengthening fulfillment practices.

Shoplogix

Shoplogix is a well-known software application that ranks 17 among all MES Software according to our research analysts and 3 crowd-sourced reviews from 1 source. Shoplogix is most suitable for mid-to-large -sized enterprises. Shoplogix can be deployed online and is accessible from a fewer number of platforms including Windows and Linux devices.

FactoryPro

FactoryPro is a popular software platform that ranks 18 among all MES Software according to our research analysts. FactoryPro is most suitable for any business. FactoryPro can be deployed on-premise and is accessible from a limited amount of platforms including Windows devices.

Sepasoft

Sepasoft helps its customers control, track and document raw materials’ transformation into finished goods in real time. It enables users to respond to production issues, identify and focus efforts on downtime and configure dashboards for everyone within the organization. Its statistical process control module facilitates collaboration and quality data analysis across the enterprise. It offers sample scheduling, automatic signal evaluation, data collection and robust charting capabilities. It empowers producers to manage, distribute and view SOPs, MSDSs and other documents with its document management inclusion.

SAP MES

SAP MES is designed to control, monitor and automate manufacturing processes and operations. It improves visibility into manufacturing processes with real-time information. It offers role-based touch screen interfaces to support workflows. It analyzes performance data to provide users with insights to increase efficiency and save costs. It triggers predetermined non-conformance processes in case of deviations from production specifications.

Siemens MES

Siemens MES is a web-based manufacturing application that helps with scheduling, document control, product history, quality control management and process orchestration. It gives users the ability to see live process data from all levels of the organization, improving the quality and efficiency of processes. As a cross-industry platform, it can be installed with limited scope or as a complete system and customized based on requirements. Users can manage multiple sites and integrate with product development and business management systems.

ShopVue

ShopVue is a popular software solution that ranks 22 among all MES Software according to our research analysts and 12 crowd-sourced reviews from 1 source. Starting from $1, ShopVue is priced cost-effectively, commonly offers a free trial and is most advisable for medium-to-large-sized businesses. ShopVue can be deployed in the cloud and on-premise and is accessible from a limited number of platforms including Windows and Linux devices.

Forcam

Forcam is a manufacturing execution system designed to improve efficiency, reduce operating costs and ensure liquidity through optimal resource utilization. It reduces machine downtime and increases productivity with precise real-time data from factories. Its performance analysis module collects critical production data to prepare meaningful reports. It calculates personnel costs incurred for products for unit cost planning. Its digital planning board provides orders’ central display and maximizes capacity utilization on the shop floor.

Tecnomatix

Tecnomatix is a popular application that ranks 24 among all MES Software according to our research analysts. Tecnomatix can be deployed on-premise and is accessible from a few platforms including Windows devices.

Statii

Statii is a cloud-based system designed for small companies to plan manufacturing and purchasing activities and schedule deliveries. It controls all business processes from costing and estimating to invoicing. It facilitates communication between team members to coordinate activities. Its production planning module creates work orders that give instructions on performing individual tasks. Inventory management sets minimum stock levels and notifies users automatically when the levels are insufficient to fulfill live orders.

Syncade

Syncade offers comprehensive services to help its users meet plant-specific needs and drive production goals. Its asset performance management module streamlines asset management, improves availability and optimizes operational performance. It offers a consolidated network view and visualization and diagnostic summaries for quick troubleshooting through network management. Its location awareness offering includes geofencing, safety mustering and alerts to ensure facility protection.

Mestec

Mestec is a well-known application that ranks 27 among all MES Software according to our research analysts and 4 crowd-sourced reviews from 1 source. Starting from $130.86, Mestec is priced within reason and is most advisable for any company. Mestec can be deployed in the cloud and on-premise and is accessible from a limited number of platforms including Windows devices.

MPDV

MPDV helps monitor, control and optimize production processes. It provides a manufacturing analytics module that includes various methods and functions to analyze data and create ad hoc reports. The advanced planning and scheduling offering, FEDRA, uses optimal resources, improves labor utilization, minimizes maintenance costs and maximizes productivity. Its shop floor integration services facilitate automated data collection for greater transparency and better responsiveness on shop floors.

Cogiscan

Cogiscan helps electronic producers boost productivity, reduce waste and leverage higher margins. Its Co-NECT interface accumulates real-time information from diverse equipment on factory floors and communicates it with other machines to improve connectivity and operations. It offers Factory Intelligence, a web-based dashboard, to help users monitor machine behavior and plan corrective actions to maintain the expected performance.

Opcenter

Opcenter provides end-to-end visibility into processes to identify bottlenecks and amend existing processes. It provides capabilities such as advanced planning and scheduling, execution, quality management, manufacturing intelligence, performance and research and development. The performance analysis reports include metrics like resource utilization and availability, product unit cycle time, conformance to schedules and performance to standards.

Werum

Werum specializes in process development, commercial manufacturing and packaging for pharmaceutical and biopharmaceutical manufacturing companies. It supports major industry segments such as vaccines, solids, liquids and other operations through its PAS-X offering. It promotes universal connectivity through standardized interfaces for seamless information exchange and higher performance. It optimizes packaging processes’ performance, manages serialization and handles aggregation.

Factivity

Factivity helps businesses optimize schedules, eliminate bottlenecks, minimize scrap, shrink machine downtime and maximize labor assets. Its shop floor module tracks labor time and material usage and produces ad-hoc reports. It optimizes supply chain sequencing and scheduling and provides value stream mapping with machine monitoring. It provides advanced analytics services, including drill-down capabilities, single-plant dashboards, multi-plant consolidation and MS SQL reports.

Oracle MES

Oracle MES is a cloud-based solution enabling manufacturing organizations to streamline production cycles. It helps operators and supervisors improve productivity by efficiently recording, completing and tracking production activities priority-wise. Go paperless and input comprehensive instructions and additional component and resource information. Dashboards provide added visibility to highlight labor and resource levels and automate process metrics.

Epicor Advanced MES

Epicor Advanced MES uses Industry 4.0 tech to increase efficiency in production and performance. The on-site or cloud-support solution gathers live data automatically from operators and equipment. It removes the need for manual data collection and provides manufacturers with a seamless option for streamlining operations and production efficiency. Real-time analysis allows users to catch exceptions early, cut down on waste and increase quality. The platform utilizes open connectivity protocol, programmable logic controllers, machine interface units and PC interfaces for added usability.

AVEVA MES

Aveva MES is a process-based solution for automated production and fast-moving goods manufacturing. It uses a model-driven approach to standardize production processes. Users can adapt processes, increase productivity and quality across multiple sites. Digital operations management allows users to standardize and sync labor and equipment costs. It utilizes real-time data collection from operations and digitally managed workflows to boost productivity and compliance.

Tulip.co

Tulip provides visibility and clarity into shop floor pillars, including people, processes, machines and devices. It monitors machines to identify bottlenecks, decrease downtime and improve efficiency. Tables enable users to set up customized databases. It automates workflows and integrates with calendar and communication apps like Google Calendar, Slack, Microsoft teams and more. Manufacturing analytics let users visualize shop floor data and create real-time reports, dashboards and visualizations.

Call SelectHub for a free 15-minute selection analysis: 1-855-850-3850

Real People... with Data

We know selecting software can be overwhelming. You have a lot on the line and we want you to make your project a success, avoiding the pitfalls we see far too often.

As you get started with us, whether it be with Software Requirements templates, Comparing, Shortlisting Vendors or obtaining that elusive Pricing you need; know that we are here for you.

Our Market Research Analysts will take calls, and in 10 minutes, take your basic requirements and recommend you a shortlist to start with.

Narrow Down Your Solution Options Easily

closeApplying filters...

Search by what Product or Type or Software are you looking for