The capabilities of preventive maintenance software (a common feature of CMMS software) offer users various benefits and perks. Mainly, it helps assess and evaluate assets to ensure they are operating at peak performance for the enterprise. It helps promote predictive and preventive maintenance to steer users away from reactive maintenance routines.

Compare Top CMMS Software Leaders

Let’s take a look at some of the features and benefits of preventive maintenance software along with our analysts’ top picks.

This Article Covers:

- What Is Preventive Maintenance?

- Features

- Benefits

- Best Preventive Maintenance Software

- Final Thoughts

What Is Preventive Maintenance?

In simple terms, preventive maintenance, often known as planned maintenance, is the regular and timely upkeep of assets, machinery or vehicles. It is the proactive scheduling and planning of maintenance tasks.

Examples of preventive maintenance include cleaning, repairing, lubricating, replacing and making adjustments to parts. You carry out these tasks while the equipment is still functional; reactive maintenance is any work done after a breakdown. We’ve compiled a detailed preventive vs. reactive maintenance analysis to further explain the differences.

Even though maintenance appears to be an expensive endeavor, proper PM job scheduling can help you on equipment expenditures as opposed to depending only on reactive maintenance.

Features

Before you select preventive maintenance software for your organization, it’s important to know their major features and compare them to your requirements.

Below are some common capabilities included in preventive maintenance applications.

Work Order Management

Preventative maintenance systems help companies visualize and automate work order processes and handle maintenance tracking throughout the maintenance request cycle. This improves internal communication and reduces the need for micromanagement of technicians. Most preventive maintenance software solutions offer role-based access to work orders, allowing only authorized users to mark them as complete.

Maintenance software lets users create work order templates so engineers and planners creating work orders can communicate task information in an efficient, effective way. Preventive systems also make it easy to see what’s complete and what you still need to do with overviews of work order progress.

Building Reports

Over the long term, you’ll want reports that show when and how employees completed maintenance tasks and why they performed tasks for individual assets. Detailed reports help provide context for preventive maintenance activities and show a bird’s-eye view of how your business is running.

CMMS solutions store asset information as part of the database for reporting and analysis. It makes it easy for facility managers to identify potential problems and send out an alert.

Asset Monitoring

Sometimes called asset life cycle monitoring or ALM, this preventative maintenance feature allows users to track asset utilization, performance and costs to optimize asset performance. Users can also create warranty records directly within the system to ensure compliance and peak asset performance.

Compliance Management

A CMMS tracks every kind of maintenance and keeps a detailed record for auditing purposes. If a piece of equipment fails despite being properly maintained, regulatory agencies have no way of knowing that without these records. Plus, you won’t have to dig through a file cabinet to access this information — generating reports for audits and inspections is easy with a CMMS.

Assignment Delegation

CMMS helps automate this delegation and prevents redundancy. It offers options to create a visual system that helps individual workers stay on task because they’ll know what they need to do on any given day. They won’t duplicate someone else’s efforts because they’ll see what’s already marked as completed in the system. Directing work delegation is one of the essential types of work CMMS systems do for businesses.

Procurement

This feature may not seem like it has anything to do with predictive or preventive functionality, but hear us out. Typically, a procurement manager or team is in charge of the purchasing for any organization — that doesn’t change with the use of a CMMS. What does change is the ease with which your purchasing team can operate.

Benefits

Preventive maintenance software offers myriad benefits for users who want to improve their facility’s operations and assets’ performance.

Take a look at some common benefits below:

Create Work Orders

Work order management software can sometimes do the whole job of streamlining your work order workflows, but when you need something more robust, CMMS has your back. CMMS preventive maintenance tools can help ensure that scheduling and completing asset maintenance gets done easily and quickly, in addition to offering other capabilities.

Generate Accurate Reports

Comprehensive CMMS tools can help managers set up a range of different types of reports. Depending on the system, they can use built-in KPIs like serial and model numbers or input custom qualifiers like manufacturer, warranty and purchase information.

This is one actionable benefit of preventive maintenance solutions — businesses can evaluate the maintenance done against the specific warranties that provide value for assets. That means if something is subject to a warranty, maintenance staff and everyone else will know right away — it makes a big difference in how you tackle upkeep.

Delegate Work

For companies with a larger staff or even a department with more than three or four people, delegation is a major aspect of day-to-day maintenance work. Collaboration between the technician and operators is important. With a CMMS, individual workers can easily have different task workloads or you can assign them to territories in a building or business campus.

Mobile CMMS benefits come in handy for facilitating work delegation. You can mitigate delays that occur when users have to wait to receive work orders or parts by allowing access to the system from a huge range of devices. Employees can open work orders anywhere, at any time, and technicians can access and complete them on the go as the system delivers real-time updates.

Implement Consistent Routines

Most equipment has a developed timeline to track when maintenance workers need to service them. Whether it’s a vehicle, a mechanical assembly on a work floor or some other business asset, maintenance will often take the form of routine. This can range from occasional work such as parts replacement, inspection and/or repair to more frequent tasks like tune-ups.

Preventive maintenance systems make all these processes transparent to show they are being done consistently and universally across the business footprint. With CMMS, nothing falls through the cracks — everything gets done by the same timeline to ensure that assets are conditioned and maintained to the same standard. Also, many of these tools are customized for a particular client to ensure they fit operations well.

Users can take preventative maintenance software a step further and auto-schedule predictive maintenance checks at designated intervals. You can customize schedules by equipment priority, maintenance protocol or production cycles. This ensures consistent monitoring of all assets and prevents human error.

Compare Top CMMS Software Leaders

Monitor Real-time Asset Information

Assets are the foundation of an organization’s function, and both EAM software and CMMS offer comprehensive asset management capabilities. Asset management modules include asset monitoring and tracking — from live video feeds of physical assets to GPS fleet tracking.

Another element of asset management that CMMS focuses on is particularly useful: depreciation methods. Let’s break that down a little bit.

There are four main ways an asset’s depreciation in value can be measured: straight line, the sum of years digits, units of production and double-declining balance. A straight line is the simplest, where the expense amount remains constant over the asset’s life cycle. For every year the asset is operational, it decreases the same amount until you have spent as much maintaining or operating it as it is worth.

Double-declining depreciation occurs when there are larger expenses early in an asset’s life cycle, and then expenses peter off later. You can track assets that are more productive early in life, such as a tow truck, using this method, so organizations pay for their original cost in chunks while the asset is still producing well, rather than all at once or spread evenly over time.

Units of production depreciation varies based on the production of an asset. Suppose you produce 13 million units one quarter on a machine with a 100-million-unit estimated life span. In that case, the value will depreciate more rapidly than during a quarter when you only produce 6 million.

Sum-of-the-years-digits depreciation is similar to the double-declining method, where a higher expense occurs in the early years of an asset’s life than in later years. This method uses an asset’s estimated useful life span to calculate how much value is lost each consecutive year.

Keeping track of the depreciation rate of each asset can be challenging without a sophisticated system to input formulas into. Luckily, CMMS will do the hard work for you, tracking and estimating your assets’ depreciation.

Improve Safety and Regulatory Compliance

Your assets aren’t the only things that will thank you for utilizing preventive maintenance — so will your legal team! CMMS helps maintain regulatory compliance and make your facility an overall safer place to be. Safety starts with the layout of your facility: CMMS applications document asset and equipment locations within a facility and can track location changes, reducing delays or accidents from unexpected changes.

Your employees also benefit from the implementation of CMMS. Management can easily track health and safety information via CMMS, reducing the amount of paperwork they must fill out or store. CMMS software can also keep your employees safer by streamlining training activities, storing training documentation and ensuring there are no gaps in safety standards.

Streamline Purchasing and Procurement

With CMMS, users can create purchase requisitions directly within the system, reducing the need for external communications, emails or phone calls. This cuts miscommunications down significantly and streamlines the whole process.

Subscriptions and other set-it-and-forget-it services make procurement and purchasing easy. CMMS translates that to automated reorders. If you have a part you need to replenish consistently, you can use your CMMS to schedule reorders. Did we mention the system also matches corresponding invoices to individual purchase orders?

Establish Long-term Plans

CMMS tools also help with long-term planning beyond simple preventive maintenance and look into the future to determine peak performance outcomes. Plus, you can come in under budget with one of these affordable and free CMMS options.

Leadership teams would do well to adopt a long-term view toward asset maintenance and use. They’re looking at things like depreciation, but they are also looking at the effects work processes have on assets over time. They may be looking at when and how to decommission key pieces of equipment, when to make big purchases and when to shuffle individual pieces of equipment around in a workspace or throughout a collection of multiple business locations.

In this sense, CMMS maintenance software helps with aspects of inventory and ensures a maintained level of service for assets. It helps you understand how to maintain these items and what value they provide for operations. It even starts to show a clear picture of how a business is running, how it provides core products and services and which pieces of equipment are most valuable or important to long-term success.

Best Preventive Maintenance Software

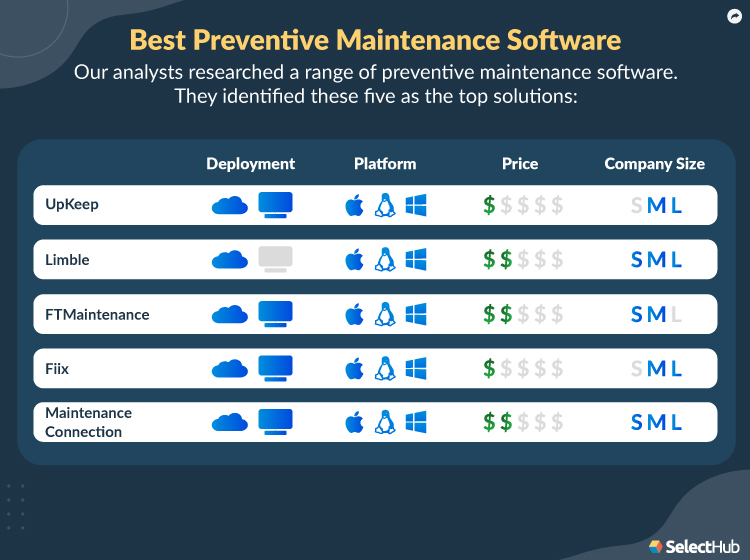

Preventive maintenance software applications optimize the maintenance process, making life easier for all involved. But which systems are the best?

Our analysts looked at many CMMS, CAFM, EAM and FM solutions on the market and used the preventive maintenance features mentioned above to identify the best of the best, so you don’t have to. Here’s what they found:

UpKeep

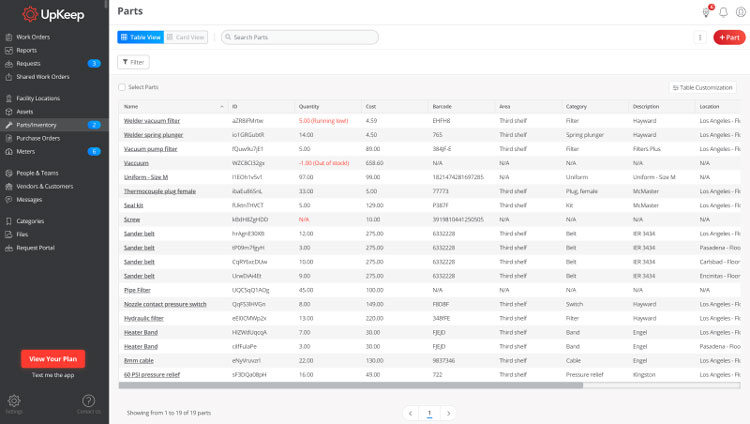

UpKeep CMMS helps property managers schedule work orders, perform preventive maintenance, manage assets and keep their facility up and running.

Track and manage work order completion by current status using UpKeep.

It helps limit unexpected downtime and optimize asset life spans.

Top Benefits

- Limit Downtime: Track asset health over time and keep a running log of asset profile information. Log downtime and cross-reference it with an asset’s work order history to better understand failure causes.

- Automate Workflows: Automate work orders to assign work to specific technicians based on location or asset type, limiting clerical work. Set the inventory management module to automatically reorder spare parts when reaching the threshold value, reducing the chances of running out of vital materials.

- Simplify Integration: Integrate with 500+ other platforms, including Google Workspace, Slack, various accounting software, Quickbooks, Zapier, etc. Integrate with Okta, Google or other SAML providers to set up single sign-on, so users don’t have to be distracted by multiple login screens. If you need more advanced integrations, access Webhooks and API for real-time data syncing.

- Filter Reports: Through visual reports and downloadable PDFs, export reports of work order history and filter those reports by asset, technician and location.

- View Usage History: Keep detailed records on asset usage, facility usage, occupancy and more. Tracks technician lockout-tagout actions for audits and logs room usage to facilitate accountability. Add notes, floorplans and a range of other documents to these histories for optimized maintenance and record-keeping.

Primary Features

- Maintenance Management: Add pre-made or create custom checklists within work orders. Use preventive maintenance scheduling to create calendar-based PMs as far out into the future as needed.

- Reporting: Gather insight into both high-level metrics and granular details. Generate reports on individual assets or whole facilities to identify which assets require the most maintenance, gauge technician efficiency, calculate work order completion rates and much more.

- Work Order Management: Role-based access lets users of various types (tenants, technicians, managers, etc.) create work order requests through the customer portal or mobile app. The requester can view the progress of their work order and edit details if necessary.

- Asset Management: Track and monitor asset performance. Get a 360-degree view of the asset life cycle, repair costs and asset information.

- Mobile App: Use the mobile app to let technicians send in-app messages to communicate with management and each other and update work orders in the field. View asset profiles, interact with checklists and attach photos of assets to document issues.

Limitations

- Difficult to export and import data.

- Cards are not invisible after work orders are closed.

- The task is only visible to the assigned person and not to team members.

Platform:

Company Size Suitability: S M L

Limble CMMS

Limble CMMS is a user-friendly platform that includes capabilities like maintenance management, inventory management, vendor management, IoT interfaces, work order management, asset management and more.

Track operation costs in Limble CMMS to avoid overspending.

It caters to companies of various sizes and industries.

Top Benefits

- Decrease Downtime: Track specified KPIs to help identify asset issues and the underlying reasons behind them to expedite the repair process. Any authorized user can report problems, ensuring they’re logged and assigned to technicians quickly.

- Create Plans Based on Data: Leverage customized and industry-standard KPI tracking to generate reports on individual assets, metrics or employee performance. Use this to create specific preventive maintenance plans based on real data gathered from operations.

- Boost Productivity: Digitized work orders, centralized ticket management and data that syncs automatically across the system streamline workflows and improve efficiency. View all relevant work orders as well as asset information, and enable users to communicate with each other from a single hub at their desktop or on the go.

- Get Organized: Receive automatically generated work orders based on priority and technician assignment to ensure employees complete work orders in a timely manner. Attach asset photos to work orders to log problems and maintain visual asset histories.

- Empower Maintenance Teams: Manage communication, work order management and preventive maintenance plans in an easy-to-use interface. Access real-time, actionable insights to stay on top of preventive repairs and crucial asset updates.

Primary Features

- Work Order Management: Organize, handle and track work orders in a centralized database accessible from any device. In a calendar interface, you may see and edit upcoming tasks by dragging and dropping them.

- Reporting: Custom dashboards provide insight into operations and visibility into the organization. Create custom KPIs to track metrics and distribute them via email.

- Inventory Management: Keep track of stock levels through receiving and shipping records. Set up push or email notifications to trigger when meeting certain thresholds to avoid low inventory. To ensure the necessary tools are in stock, technicians can search for parts and attach them to work orders.

- Asset Management: Consists of maintenance logs, asset profiles, a searchable asset database and asset hierarchies that organize parent-to-child relationships. Managers can use IoT sensors and QR code scanning to track KPIs and view real-time reports on asset information.

- Mobile App: Native iOS and Android apps improve communication and streamline the maintenance workflow. Provides a leaner set of features tailored to the needs of field technicians, such as speech-to-text, work order logs, push notifications and asset search.

Limitations

- Limited capabilities on the mobile app compared to the site.

- Alerts don’t include text that describes the notification.

- Doesn’t mention stock withdrawal/return per work order.

Platform:

Company Size Suitability: S M L

FTMaintenance

FTMaintenance is a feature-rich and user-friendly solution that allows organizations to control their maintenance program completely.

Manage inventory and stock levels with FTMaintenance.

Executives, maintenance managers and technicians can use a unified interface to document, manage and track all maintenance activities.

Top Benefits

- Scalability: FTMaintenance grows with your business. You can start small and scale up to accommodate a growing maintenance team, other departments within your organization and additional locations.

- Rapid Deployment and Startup: Get your system up and running quickly so you can start reaping the benefits of your maintenance management software right away.

- Support Network: Take advantage of the highly-responsive support team to clear doubts and troubleshoot technical problems.

- Quick Work Order Closure: Guide employees through work orders in a stepwise manner. Improve data entry by creating an approval process and customizing fields.

- Paperless Processes: Replace hard copies, manuals and spreadsheets by bringing all information about assets, equipment and inventory into one centralized database.

Primary Features

- Asset Management: Manage all company assets and equipment. Keep information such as bills of materials, service history and work orders in a central location for easy access by team members.

- Work Order Management: Generate and track work orders automatically. Plan ahead with a flexible maintenance calendar that includes schedule views to automate work order assignment, distribution and activation.

- Inventory Management: Keep track of MRO inventory across multiple facilities. Keep inventory counts up to date by sending out automated notifications when supplies are running low.

- Maintenance Reports: With over 140 built-in templates, you can create comprehensive maintenance reports. To make informed business decisions, analyze data using customizable filters and data views.

- Mobile Accessibility: Access work orders from anywhere, at any time. Enable field maintenance personnel to use mobile devices to create, track and update maintenance activities.

Limitations

- Default reports are limited.

- Difficult to choose and edit custom fields.

- Printing issues after PMs are released.

Platform:

Company Size Suitability: S M L

Fiix

Fiix offers cloud-based computerized facility and maintenance management software that helps teams organize their assets, manage repair work, integrate their operations through connected business platforms and make data-based decisions.

Manage parts and supplies in different locations with Fiix.

It manages assets in multiple locations and streamlines workflows.

Top Benefits

- Organize Assets Hierarchically: Set priorities and keep track of vital asset information by creating asset hierarchies with custom categories, asset grouping and profiles.

- Manage Multiple Sites: Coordinate sites all over the world with real-time data. Managers can set sites to different time zones, standardize currency and perform operations in various languages.

- Manage Employee Certifications: Track workforce certifications and receive an alert when qualifications are nearing expiration for groups or individuals to ensure compliance and safety.

- Decrease Downtime: Decrease unexpected downtime with preventive maintenance plans and detailed asset tracking.

- Streamline Workflows: Automatically assign work orders or maintenance tasks to a team or individual to expedite the completion process.

Primary Features

- Multi-Site Management: Help facility managers coordinate multiple sites in real time across time zones, languages and currencies. The rotating asset tracking feature helps manage assets, such as tools, vehicles and spare parts, between facilities.

- Failure Codes: Use pre-loaded common failure codes. These standardized codes support workflows and de-escalate issues.

- Spare Parts Management: Itemize spare parts and other materials in a centralized database for searchability and organization. Set alerts for low-stock thresholds and reorders.

- Search Tool: Easily search the asset repository using nameplate information, identifying details and other data.

- Multiple Asset Functionality: Asset hierarchies keep asset relationships organized and centralize information into a single database. You can customize categories to group assets and establish SOPs for related assets. Create a single work order for multiple assets.

Limitations

- Complex to understand, providing non-essential or limited information.

- Difficult to navigate and make changes in the initial stages.

- Can’t send emails to multiple users.

Platform:

Company Size Suitability: S M L

Maintenance Connection

Maintenance Connection offers the whole gamut of asset and maintenance management features that help users manage the life cycles of their physical assets.

Manage purchase orders on one dashboard with Maintenance Connection.

It comes in on-premise, cloud or hybrid deployments and is highly scalable to fit a diverse clientele.

Top Benefits

- Extend Asset Life Span: Asset tracking, condition monitoring, predictive/preventive maintenance and more help keep assets operating at peak performance to the extent of their useful life span.

- Manage Maintenance: Calendar-based maintenance scheduling facilitates preventive/predictive maintenance plans. Automated reminders trigger when routine maintenance is due, reducing the likelihood of crucial upkeep tasks falling through the cracks.

- Assign Asset Hierarchies: Assign a custom hierarchy to assets so technicians can prioritize emergency repairs if, for example, a severe weather situation damages multiple assets. This helps protect the most important assets and keep technicians on task.

- Reduce Asset Downtime and Failure: PM plans reduce asset downtime by improving asset health awareness and reducing the wear and tear on equipment. This cuts down on unplanned downtime by keeping assets in peak condition and significantly decreases the chances of catastrophic failures.

- Improve Productivity: Boost organizational and labor pool productivity using work order management. Assign tasks to individual technicians and streamline the workflow from creation to completion to expedite the process.

- Improve ROI: Realize organization-wide benefits and greater profits when technicians are more efficient, assets are operational most of the time, and the chances of unexpected catastrophic failure (and the huge cost of asset replacement that often accompanies it) are reduced.

Primary Features

- Work Order Management: Users can create, designate and track work orders. Administrators can assign them to individual technicians and schedule them for specific dates if there is a backlog of work to be completed.

- Asset Management: The drag-and-drop interface offers an intuitive way to create, search and edit asset profiles. Arrange profiles via hierarchy, location, operational status and more for easy searching and cataloging.

- Preventive/Predictive Maintenance: Create both preventive and predictive maintenance plans to schedule and perform maintenance tasks. Configurable notification settings alert technicians or administrators when repetitive maintenance tasks are due and deliver the associated work order into the work queue.

- Inventory Management: Whether the inventory is spare parts, raw materials or a finished product ready for distribution, automated inventory management makes it easier to manage. Barcode generation, cost tracking, part categorization, min-max value reordering and text notifications when stock levels reach minimum thresholdsare some other capabilities.

- Reporting: Leverage statistical reports with 150 pre-built designs and a range of customizable formats to gain insight into operations.

Limitations

- Doesn’t support dispatch management.

- Provides limited options for creating ad-hoc or custom reports.

- Printing a task list in a readable format can be difficult.

Platform:

Company Size Suitability: S M L

Final Thoughts

Preventive maintenance features of CMMS are useful in a variety of ways, but the way the benefits of preventative maintenance program resources assist enterprise leaders are especially crucial. Through principles of preventive maintenance, companies can be sure that they are competing well in industries that depend on having the best and most well-maintained infrastructure in place.

Check out our CMMS comparison matrix if you want to see how different CMMS vendors compare for these key functions.

What other benefits does CMMS preventive maintenance software provide your organization? Which CMMS, EAM or FM product do you use? Let us know your thoughts in the comments!

Analyst-Picked Related Content

Pricing Guide: Discover the true cost of CMMS software

Comparison Report: An interactive analyst report with comparison ratings, reviews and pricing for CMMS software

3 comments

Join the conversationKristofer Van Wagner - June 24, 2020

I like that this post pointed out that a CMMS software is excellent at streamlining the workflow. This is an amazing benefit for businesses as it will surely help increase the productivity level while ensuring the operation runs smoothly and in an orderly manner. If I know anyone who can benefit from this, especially someone who handles a lot of logistics or supply and demand, I will definitely recommend Maintsmart.

Bergen Adair - July 6, 2020

Thanks for reading and recommending, Krisotfer!

Lamint - March 30, 2017

Preventive maintenance is considered as an important part of a perfect maintenance strategy. A smart manager is the one active in performing regular maintenance activities: from inspecting the areas of risk that may causing breakdown and then setting out a good maintenance plan, keeping track of all work orders to assessing the overall results of preventive maintenance strategy. Using IT benchmark on maintenance may be a modern tendency in maintenance nowadays.